In a quiet factory corner in Manchester, a machine hums softly as it builds a complex aerospace component layer by layer—this is AMT additive manufacturing at work, transforming how we think about production, waste, and possibility. What once seemed like science fiction has become the backbone of modern manufacturing, where digital files transform into tangible objects with precision that would have seemed impossible just decades ago.

The story of additive manufacturing isn’t merely about technology; it’s about reimagining the very foundations of how we create. From the aerospace engineer designing lighter aircraft components to the medical professional crafting patient-specific implants, this technology has woven itself into the fabric of innovation across industries.

The Technology That Builds Dreams Layer by Layer

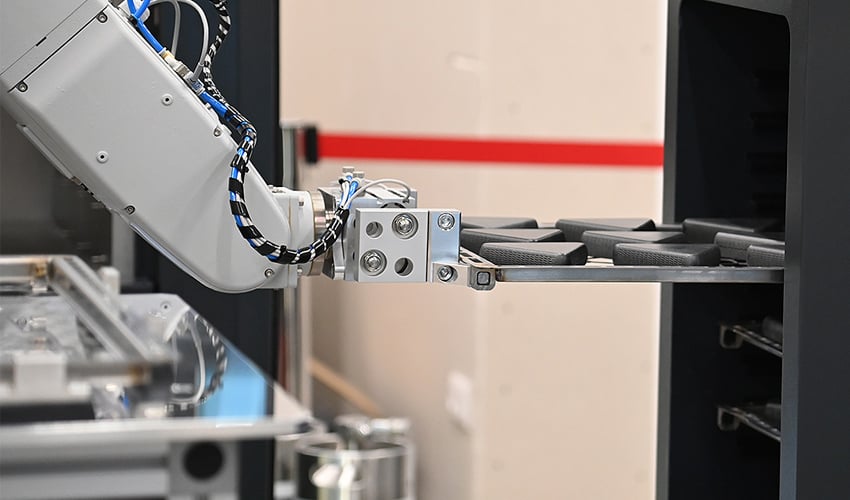

At its core, additive manufacturing represents a fundamental shift from traditional subtractive methods. Rather than carving away material to reveal a final product, this process builds objects by adding material layer upon layer, guided by precise digital instructions. The elegance lies not just in the method, but in the possibilities it unlocks.

Consider the complexity that becomes achievable: internal channels that could never be machined, lattice structures that optimise strength whilst minimising weight, and geometries that exist only in the realm of mathematical perfection. These aren’t merely manufacturing improvements; they’re leaps forward in what’s physically possible to create.

Transforming Industries Through Intelligent Design

The impact reaches far beyond the factory floor. In aerospace, components that once required assembly from dozens of parts can now emerge as single, integrated structures. The automotive industry discovers new ways to create lightweight yet durable components. Medical professionals craft prosthetics and implants tailored to individual patients with unprecedented precision.

Key advantages driving this transformation include:

- Design Freedom: Complex geometries previously impossible to manufacture become achievable

- Rapid Prototyping: From concept to physical prototype in hours rather than weeks

- Customisation: Each product can be individually tailored without retooling

- Material Efficiency: Minimal waste compared to traditional manufacturing methods

- Supply Chain Simplification: Digital files replace physical inventory for many components

The Singapore Success Story

Singapore has emerged as a global leader in additive manufacturing adoption and innovation. As Dr. Lim Wei Chen, Director of the Singapore Centre for Advanced Manufacturing Technologies, observes: “Singapore’s strategic investment in AMT additive manufacturing infrastructure has positioned us as a hub for next-generation production capabilities. We’re not just adopting this technology; we’re pioneering new applications that will define the future of manufacturing across Southeast Asia.”

This commitment extends beyond mere adoption. Singapore’s approach encompasses research institutions, government support, and industry collaboration, creating an ecosystem where additive manufacturing thrives. The nation’s strategic position as a manufacturing and logistics hub amplifies these capabilities, making it an ideal testing ground for breakthrough applications.

Overcoming the Challenges of Tomorrow

Yet this revolution isn’t without its obstacles. Quality control requires new methodologies when traditional inspection techniques fall short. Material properties must be understood and optimised for layer-by-layer construction. Skills gaps emerge as traditional manufacturing expertise doesn’t always translate directly to additive processes.

The learning curve extends beyond technical challenges to encompass design thinking itself. Engineers must reimagine how products should be conceived when the constraints of traditional manufacturing no longer apply. This mental shift—from designing for manufacturing limitations to designing for optimal performance—represents perhaps the greatest challenge and opportunity.

Economic Implications and Market Dynamics

The economic implications ripple through entire supply chains. Inventory strategies shift when products can be manufactured on-demand. Transportation costs diminish when production can occur closer to end users. The very concept of economies of scale evolves when customisation becomes as economical as mass production.

Small businesses gain access to manufacturing capabilities previously reserved for large corporations. Entrepreneurs can test market demand with small production runs before committing to large-scale manufacturing. The democratisation of production tools creates new opportunities whilst challenging established market dynamics.

Future Horizons and Emerging Possibilities

Looking ahead, the convergence of additive manufacturing with artificial intelligence, machine learning, and advanced materials science promises even more dramatic developments. Self-optimising designs, predictive quality control, and materials engineered at the molecular level point towards manufacturing capabilities that seem almost magical.

The integration with Industry 4.0 concepts creates smart factories where additive manufacturing systems communicate, adapt, and optimise automatically. Real-time monitoring, predictive maintenance, and adaptive quality control transform manufacturing from a mechanical process into an intelligent, responsive system.

The Path Forward

As we stand at this technological crossroads, the question isn’t whether additive manufacturing will reshape industry—it’s how quickly and completely this transformation will occur. The companies and nations that embrace this change, invest in the necessary infrastructure and skills, and reimagine their approach to production will find themselves at the forefront of the next industrial revolution.

The quiet machine in that Manchester factory represents more than a manufacturing tool; it embodies a fundamental shift in how humanity approaches creation itself. As industries worldwide recognise this potential and adapt their strategies accordingly, we witness the continuing evolution of AMT additive manufacturing.